IR-Triazine (Grotan BK Equivalent)

Product Info:

The main production process of Grotan BK is to add ethanolamine after the preprocessed methanol and stir for two hours. Then preserve the temperature for another hour. Terminator is properly added to prevent the side reaction. The solution is filtrated after being settled, then concentrated with some auxiliaries.

CAS No.:

4719-04-4

EC No.:

225-208-0

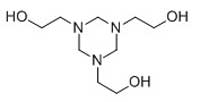

Molecular Formula:

C9H21N3O3

Structure Formula:

Properties:

IR-Triazine is a good equivalent of Grotan BK. This Grotan BK equivalent is usually mostly applied as desulfurized and anti-mildew agent.

As desulfurized, IR-Triazine is mainly used to remove the H2S generated from the exploitation of crude oil and natural gas, thus guaranteeing health in the production field and reducing the H2S corrosion to equipment.

By injecting into the desulfuration process, IR-Triazine has the following advantages in low H2S situations: convenient operation, low cost, and less operation area. It is suitable for offshore and onshore oilfields with stricter requirements in space and investment.

Being an anti-mildew agent, IR-Triazine is definitely the main ingredient of Grotan BK. This Grotan BK is widely used in metal processing (cutting and grinding fluid), papermaking (paper coating), painting and coating, electroplating, and leather (clustering agent).

Specifications:

| Items | Index |

|---|---|

| Appearance | Colorless or light yellow transparent liquid |

| Active acid (by titration) % | 74-78 |

| Refractive Index | 1.47-1.49 |

| pH(as it) | 9.0-12.0 |

| Density (25℃, g/cm3) | 1.15-1.16 |

Usage:

As desulfurized, IR-Triazine can be directly put into the desulfurization process. For high-sulfur crude, the advised amount to use is 0.3-0.5%.

Being an anti-mildew agent, the dosage depends upon the situation using the following reference.

| Industry | Recommended Dosage |

|---|---|

| Papermaking | 0.05-0.1% |

| Oil industry | 0.01-0.05% |

| Metal Processing | 0.15-0.3% |

| Painting and Coating | 0.2% |

| Electroplating | 0.2-0.3% |

| Detergent | 0.2-0.3% |

Packing:

200L plastic drum, 1000L IBC tote. Non-hazard Chemical.