Tetrakis(hydroxymethyl)phosphonium chloride (THPS)

CAS No.:

55566-30-8

Molecular Formula:

C8H24O12P2S

Molecular Weight:

406.27

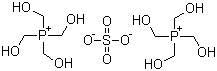

Structure Formula:

Properties:

Tetrakis(hydroxymethyl)phosphonium chloride is a type of environmental-friendly water treatment micro biocide that is made of THPS chemicals. It can easily withhold sulfate-reducing microorganisms.

Most of the aerobic bacteria such as microorganisms form biofilm inside the enhanced oil process of recovery, manufacturing, and also other supporting systems. For example water injection equipment, well water disposal facilities, water holding tanks, recirculating water treatment systems, as well as pipelines.

Tetrakis(hydroxymethyl)phosphonium chloride can also be good at managing bacterial development in drilling muds and also stimulation liquids for gas and oil wells. The THPS biocide is actually known for its low solidity point and excellent stability.

THPS 75% solution can simply dissolve in water and also can be maintained for a long period. In 1995, the United States environmental protection agency ratified it with absolutely no toxicity and awarded it with US green chemical prize because of its characteristics associated with high efficacy, low toxicity and, also low rudimental.

IRO Biocide is one of the reliable TPHS manufacturers and suppliers of THPS 75 solution and tetrakis(hydroxymethyl) phosphonium sulfate. We always supply high-quality THPS biocide products like Aqucar THPS 75%.

Synthesis Methods:

Tetrakis(hydroxymethyl)phosphonium chloride is synthesized by the following methods.

- Using hydrogen chloride as the catalyst and phosphine and alkyl aldehydes as the reaction raw materials.

- Using formaldehyde and phosphine as reaction raw materials, controlling pressure and temperature in a certain range, formaldehyde phosphine reacts in the presence of a small amount of dispersed metal or compound, through a two-step sequential reaction, i.e., using phosphine with excess formaldehyde under high-pressure, controlling a certain temperature to obtain a solution of trimethylolphos hemiacetal, and finally treated with acid.

- Metal phosphide, formaldehyde, and inorganic acids are used as raw materials.

Specifications:

| Item | Index |

|---|---|

| Active Content, % | 75.0 Min. |

| Viscosity (at 25°C) | 30.0~36.0mPa.S |

| Density (at 25°C) | 1.350~1.420 |

| Fe, % | 0.002 Max. |

| pH Value | 2.5~5.0 |

Uses:

Tetrakis(hydroxymethyl)phosphonium chloride uses are so wide. Now, let’s see how useful it is.

- Water Treatment

Tetrakis(hydroxymethyl)phosphonium chloride (THPS) should be added to a waterflood system at a point where uniform mixing will occur.

First step: add 93 -350 ppm THPS chemical for a noticeably fouled system. When added to a flowing system, slug dose for 2 -6 hours based on flow rates. Repeat as necessary until control is achieved.

Second step: once control has been achieved. Add 14 -98 ppm THPS biocide weekly or as needed to maintain control. As for continuous treatment, THPS can be dosed continuously at a level of 14 -67 ppm.

- Oil and Gas Production and Transmission Systems and Pipeline

THPS 75% solution should be added at a point in the pipeline where uniform mixing will occur.

The application should be conducted to ensure maximum distribution of products through the internal surface of the pipeline by adding an amount of biocide which eventually comes out the other end of the pipeline.

The criteria for the success of the treatment will be a reduction in the bacterial count and/or corrosion rates. Adding steps is the same as that of water flooding. As for continuous treatment, tetrakis hydroxymethyl phosphonium sulfate can be dosed continuously at a level of 14 -100 ppm.

- Drilling Muds, Well Completion, and Workover Fluids

THPS 75 should be added to these fluids at a point where uniform mixing will occur. Add 33-1400 ppm of product to a freshly prepared fluid depending on the severity of contamination.

- Gas Storage Well systems

Individual injection wells should be treated with THPS 75% at the same dosage and same steps as described underwater flooding.

Injections should be repeated as needed to maintain control.

Individual drips should be treated with a sufficient quantity of product to produce a concentration of 33.3 -133.3 ppm when diluted by the water present in the drip.

Injections should be repeated as needed to maintain control.

Some oilfield drilling service companies in the US and Canada started to use Xanthan gum, THPS biocide, and Curdlan gum in the water flooding process. Here is a course drafted by Dr. Georgy Zerkalov from Stanford University.

Packing and Storage:

Packed in 250 Kg plastic drums, sealed and stored.

References:

- Tetrakis(hydroxymethyl)phosphonium Chloride (5046) from Wikisource.

- National Library of Medicine National Center for Biotechnology Information

- Tetrakis(hydroxymethyl)phosphonium chloride – Wikipedia

Attachment:

Click PDF page to download THPS biocide MSDS.